2026 Best Refrigerated Sea Container Options for Your Shipping Needs?

As global trade continues to expand, shipping needs are evolving. The demand for refrigerated sea containers has never been higher. These containers are vital for transporting perishable goods. They ensure products like fruits, vegetables, and meats remain fresh during transit.

In 2026, choosing the best refrigerated sea container options is crucial for businesses. Factors like size, temperature control, and energy efficiency can impact shipping costs and product quality. Companies must reflect on their specific requirements. Selecting the right container often requires balancing budget constraints with operational needs.

While some companies focus solely on price, others recognize the value of quality. Investing in a reliable refrigerated sea container can prevent spoilage and boost customer satisfaction. It's essential to evaluate available options carefully. Ignoring minor details could lead to significant losses. Understanding these aspects leads to better decision-making, ultimately enhancing the shipping experience.

Best Types of Refrigerated Sea Containers for Your Shipping Needs

When considering the best types of refrigerated sea containers for shipping, there are several options to explore. The two main types are standard reefers and specialized containers. Standard reefers are versatile and widely used, ideal for various perishable goods. These containers maintain temperatures between -30°C to 30°C, catering to a range of products like seafood, fruits, and pharmaceuticals.

Specialized containers, on the other hand, cater to specific needs. For instance, some refrigerated containers feature advanced temperature control systems. These systems can manage different temperature zones within a single container. According to industry data, about 45% of transported perishables in 2022 required specialized handling. This proves that relying on standard options may not suffice for all cargo.

Smart technology is also making its way into refrigerated sea containers. IoT-enabled reefers can provide real-time monitoring. Despite the advantages, challenges remain. Some companies report technical issues with sensors or connectivity. This can hinder operational efficiency. The balance between cost, efficiency, and technological advancements is difficult to achieve. The industry must reflect on these aspects for future improvements.

Key Features to Consider in Refrigerated Sea Containers

When choosing refrigerated sea containers, several key features are crucial. The temperature control range is primary. Typically, these containers maintain temperatures from -30°C to +30°C, optimizing for various cargo. This is especially vital for sensitive goods, as losses can soar over minor temperature fluctuations. A report by the Food and Agriculture Organization indicates that spoilage due to improper temperature management can lead to over $30 billion in losses annually.

Another feature to consider is insulation quality. High-density foam or polyurethane insulation ensures minimal heat transfer. It maintains the internal environment, combating external temperature changes. Less efficient insulation can yield higher energy costs and risk product degradation. The International Maritime Organization has noted that inadequate insulation leads to energy inefficiency, increasing the overall carbon footprint of shipping.

Monitoring systems are also essential. Advanced GPS and temperature monitoring technologies allow real-time tracking. This enhances security and ensures compliance with shipping regulations. However, not all systems offer the same reliability. Some older models may not integrate modern tech smoothly. This can create gaps in data, leading to potential compliance issues. It's crucial to reflect on these advancements while selecting a container that balances technology and cost.

Comparative Analysis of Leading Refrigerated Container Brands

In the world of refrigerated sea containers, choosing the right option is vital for maintaining product integrity. A recent industry report highlighted that 30% of shippers experience temperature-related issues during transit. This statistic reveals the importance of selecting reliable brands. Different manufacturers offer unique features. These can impact temperature accuracy and energy efficiency.

Many refrigerated containers boast advanced refrigeration technology. Some units can maintain temperatures as low as -20°C. However, not all containers achieve this consistently. A survey from 2023 indicated that only 75% of containers kept the required temperatures throughout a journey. This inconsistency can lead to spoilage, affecting businesses.

Investing in a high-quality refrigerated container can reduce risk. Many options are available, but not every brand meets the necessary standards. It’s crucial to consider the maintenance procedures as well. Regular checks can ensure optimal performance. In a competitive market, every detail counts. Businesses should evaluate multiple factors before making a decision. Carefully reviewing performance history is essential.

2026 Best Refrigerated Sea Container Options for Your Shipping Needs

| Container Type | Temperature Range (°C) | Capacity (CBM) | Power Source | Weight (kg) | Features |

|---|---|---|---|---|---|

| Standard Reefer | -20 to +25 | 30 | Electric | 3000 | Dual Temperature Control |

| High Cube Reefer | -30 to +30 | 36 | Diesel/Electric | 3500 | Advanced Insulation |

| Multi-Temp Reefer | -25 to +25 | 40 | Electric | 3200 | Flexible Temperature Zones |

| Controlled Atmosphere Reefer | -30 to +15 | 28 | Electric | 3100 | Atmospheric Control Technology |

| Insulated Reefer | -15 to +20 | 25 | Passive | 2800 | Eco-Friendly Materials |

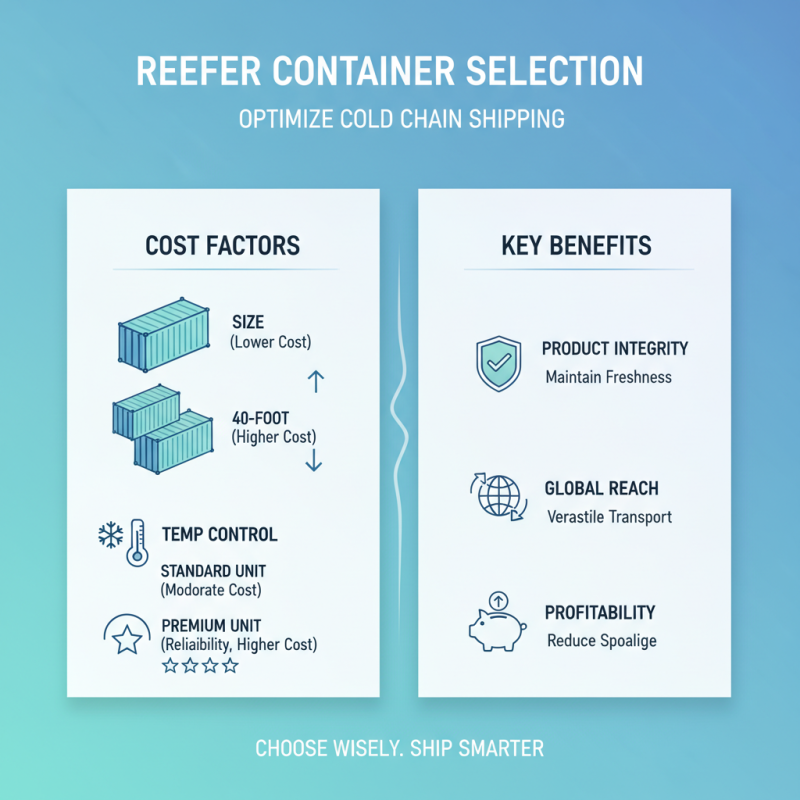

Cost Factors Involved in Refrigerated Sea Container Options

Choosing the right refrigerated sea container is vital for your shipping needs. Cost factors play a significant role in this decision. The size of the container greatly affects pricing. Standard 20-foot containers could cost less than larger 40-foot models. Moreover, the temperature control system also impacts the overall expense. High-quality refrigeration units may carry a premium price but provide better reliability.

Another factor is the duration of rental or purchase. Short-term rentals usually have higher daily rates, while long-term agreements can lower your overall costs. Additionally, shipping distance can introduce further expenses. Containers may require insulation or additional features if traveling to extreme climates.

One must not overlook maintenance costs. Regular servicing is essential for optimal performance. Unexpected repairs can strain budgets. Proper planning can prevent these surprises. Evaluating all these factors ensures more informed decisions when choosing refrigerated options. Balancing initial costs with long-term benefits is both an art and a necessity.

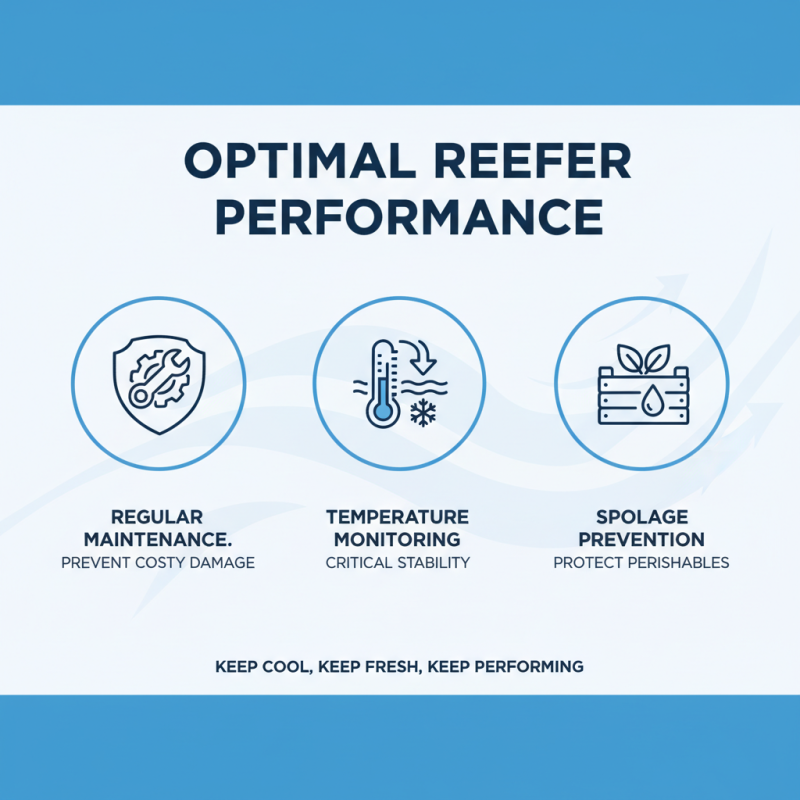

Maintenance Tips for Optimal Performance of Refrigerated Containers

When using refrigerated containers, maintenance is key for optimal performance. Regular checks can prevent costly damages. One major aspect is temperature monitoring. Ensure that your container maintains the required temperature levels. A small fluctuation can spoil perishable goods.

Perform routine inspections to check the seals and insulation. Look for any signs of wear. Broken seals can lead to temperature loss. It's easy to overlook these details, but they matter greatly. Diligent care can prolong the life of your container.

Another important tip is to clean the interior regularly. Residues can lead to contamination. Use mild detergents suitable for food. Follow manufacturer guidelines to avoid damage. Remember, every step counts in maintaining your refrigerated container.

Related Posts

-

Best 10x10 Storage Container Options for Maximum Space Utilization

-

How to Use a 30 Foot Shipping Container for Your Next Project

-

2026 Best Uses for a 40ft Container in Your Projects

-

Top 10 Benefits of Using ISO Containers for Your Shipping Needs

-

What is a 10x10 Storage Container and How Can It Benefit Your Space

-

Top Benefits of Using Cold Storage Containers for Food and Products