How to Choose the Right Cold Storage Container for Your Needs

When it comes to preserving the quality and integrity of perishable goods, selecting the right cold storage container is paramount. These specialized containers are designed to maintain a controlled environment, ensuring that temperature-sensitive items remain fresh and unspoiled. However, with a vast array of options available on the market, choosing the most suitable cold storage container for your specific needs can become a daunting task.

The process involves understanding various factors, such as the type of items you plan to store, the duration of storage, and the temperature requirements. Different cold storage containers offer unique features, such as insulation properties, size, and portability. Furthermore, recognizing whether you need a container for short-term use, such as transporting food for a party, or for long-term storage of pharmaceuticals or biological samples, will greatly influence your decision. By carefully considering these factors, you can make an informed choice that aligns with your needs, ensuring optimal preservation of your valuable items.

Understanding Cold Storage Container Types and Their Uses

When choosing a cold storage container, it is essential to understand the various types available and their specific applications. The most common types include portable refrigeration units, bulk storage freezers, and refrigerated shipping containers. Portable refrigeration units are ideal for small-scale operations and events that require temporary cooling solutions. Their mobility allows users to easily transport perishables while maintaining optimal temperatures. These units are often used for catering services, farmers’ markets, or short-term storage in remote locations.

On the other hand, bulk storage freezers and refrigerated shipping containers are designed for larger quantities of goods that need to be stored or transported over extended periods. Bulk storage freezers are beneficial for commercial kitchens, food distribution centers, and warehouses, providing efficient and reliable storage for large volumes of frozen products. Refrigerated shipping containers, commonly used in the logistics sector, are excellent for ensuring that temperature-sensitive goods, such as pharmaceuticals or seafood, remain within safe temperature ranges during transit. Understanding these container types and their specific uses will help you make an informed decision that best suits your cold storage needs.

Cold Storage Container Types and Their Uses

Evaluating Insulation Materials and Their Efficiency Ratings

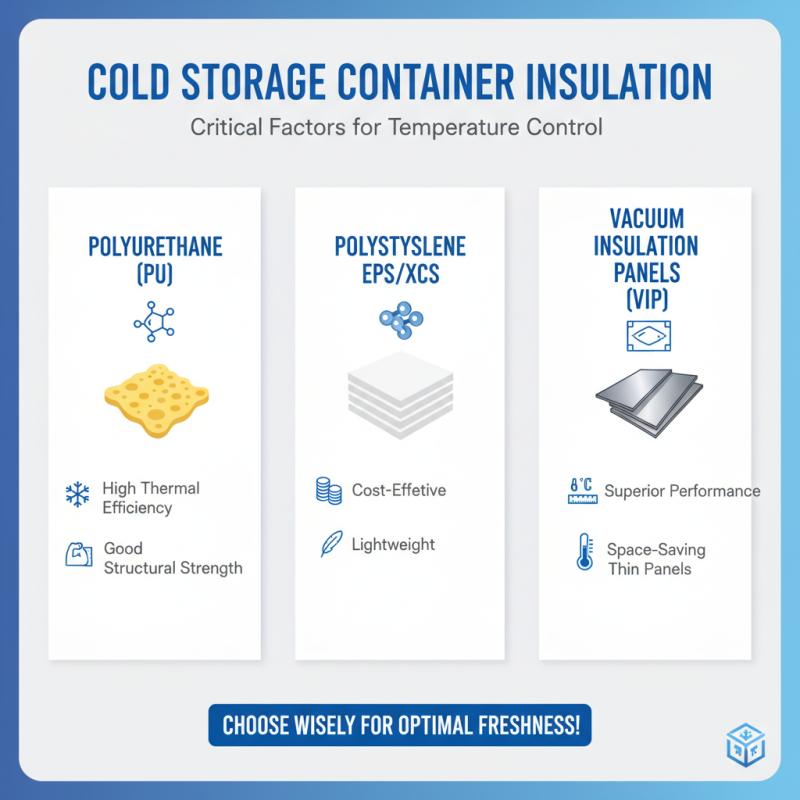

When selecting a cold storage container, one of the most critical factors to consider is the insulation material used in its construction. Insulation plays a vital role in maintaining the internal temperature of the container, ensuring that perishable goods remain fresh for longer periods. Different materials offer varying levels of thermal efficiency, so understanding the properties of these materials is essential. Common insulation materials include polyurethane, polystyrene, and vacuum insulation, each with its unique benefits and drawbacks.

Polyurethane foam is known for its high insulation efficiency, providing an excellent thermal barrier. This material can significantly reduce heat transfer, making it ideal for long-term storage needs. Polystyrene, while slightly less efficient than polyurethane, is a lightweight and cost-effective option that still offers substantial insulation. For applications requiring optimal thermal performance, vacuum insulation is unparalleled; it boasts a minimal thermal conductivity rate, ensuring that containers maintain their internal temperature even in extreme conditions. Evaluating the insulation material based on efficiency ratings and thermal performance will guide you in selecting the right cold storage container tailored to your specific requirements.

Assessing Size and Capacity Requirements for Your Cold Storage Needs

When selecting a cold storage container, it's crucial to assess your size and capacity requirements carefully. Begin by evaluating the types of items you intend to store—whether they are food products, pharmaceuticals, or other perishables—as different items may have specific volume or temperature needs. Consider not only the quantity of items but also their sizes and packaging, as this will significantly influence the total space you will require.

Tips: Measure the dimensions of the items you plan to store and calculate the total volume needed, factoring in some extra space for air circulation. Additionally, think about future needs; if your storage requirement might increase, opting for a slightly larger container could save you from inconvenient adjustments later.

Another important consideration is the layout and accessibility within the storage unit. Ensure that the container allows for easy organization and access to all items. This aspect is vital for maintaining the quality of the stored goods, as frequent rearranging in tight spaces can cause deterioration.

Tips: Use shelves or bins within the container to maximize space and keep items organized. Labeling containers and maintaining a clear inventory can also enhance efficiency and help you track what you have stored, minimizing any risks of spoilage.

Comparing Cost-Effectiveness of Various Cold Storage Solutions

When considering cold storage solutions, cost-effectiveness is a primary factor that influences decision-making. Various options, such as portable cold bags, insulated containers, and commercial-grade refrigeration units, each come with different price points and operational costs. Portable cold bags, for instance, tend to be low in initial investment but might require frequent replenishing of ice or gel packs. In contrast, investing in an insulated container might present a higher upfront cost, but it could offer better thermal retention, ultimately reducing the need for constant cooling supplies.

Additionally, when evaluating commercial refrigeration units, it is essential to consider their long-term energy consumption. While they may require a significant investment initially, energy-efficient models can save costs over time through lower utility bills. Moreover, maintenance costs should also be accounted for; some models may require specialized service, while others offer easier maintenance at a lower cost. By carefully analyzing these factors, individuals and businesses can select the most suitable cold storage solution that aligns with their budget and operational requirements, maximizing both savings and efficiency.

How to Choose the Right Cold Storage Container for Your Needs

| Container Type | Initial Cost (USD) | Operating Costs (USD/month) | Temperature Range (°F) | Capacity (Cubic Feet) | Best Use Case |

|---|---|---|---|---|---|

| Portable Cold Storage | $1,500 | $150 | -10 to 50 | 100 | Events & Temporary Storage |

| Freezer Truck | $30,000 | $800 | -20 to 32 | Transportation of Frozen Goods | |

| Walk-in Cooler | $20,000 | $500 | 30 to 50 | Long-term Food Storage | |

| Chest Freezer | $600 | $100 | -20 to 0 | Home Use & Small Businesses | |

| Refrigerated Container | $5,000 | $300 | 32 to 50 | Holding Perishable Goods |

Exploring Compliance Standards and Regulations for Cold Storage Containers

When selecting a cold storage container, it is essential to understand the compliance standards and regulations that govern their use. These standards are put in place to ensure that food, pharmaceuticals, and other temperature-sensitive items are stored properly to prevent spoilage and contamination. Different industries may have specific guidelines, such as the FDA regulations for food storage or the GMP standards for pharmaceuticals. Familiarizing yourself with these requirements will help you choose a container that not only meets your specific needs but also adheres to legal obligations.

In addition to industry-specific regulations, it is crucial to consider the insulation properties, temperature control capabilities, and monitoring systems of the cold storage containers. Containers must maintain the appropriate temperature range consistently, as fluctuations can lead to compliance issues and ultimately impact product safety. Moreover, understanding how to document and prove compliance with these regulations is equally important. Implementing regular checks and maintaining accurate records can assist in demonstrating adherence to the required standards and safeguarding your operations against potential liabilities.

Related Posts

-

2025 Top 10ft Storage Container Options for Your Storage Needs

-

Top 10 Uses for Large Shipping Containers in 2025: Innovative Ideas and Tips

-

What is a 30ft Container? Understanding Its Uses and Benefits for Storage

-

2025 Top Benefits of Using 20ft Refrigerated Containers for Your Business

-

Best 10x10 Storage Container Options for Maximum Space Utilization

-

How to Choose the Right 10x10 Shipping Container for Your Needs